BARQ Rebar Couplers

Mechanical Splicing System

Complete Solution for your Construction Projects

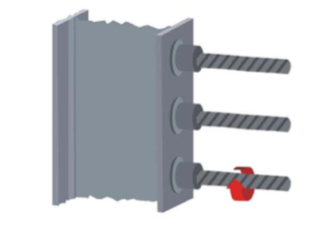

BARQ Rebar Couplers are designed to join the reinforcement bars. The traditional method of connecting reinforcement bars with lap joints continuity in reinforced concrete need not be always appropriate. Advantages of simplicity and economy in lap splicing is limited to smaller diameter bars. Sanfield mechanical couplers offer the solution for splicing for all diameter bars ranging from 12mm to 40mm.

Technically Superior: BARQ Rebar Couplers performs like continuous reinforcement, develops strength mechanically, independent of concrete. Therefore provides ductility in RCC structures independent of condition of concrete. Proven cyclic performance of rebar offers strength during man-made, seismic or other natural events.

BARQ Rebar Couplers reduce rebar congestion and improve concrete flow & consolidation. Offer greater flexibility in design options. The simplicity in detailing of reinforcement, particularly in reinforcement congestion zones minimizes the reinforcement fixing errors, detailing and fixing of seismic reinforcement becomes effortless. Workability with higher steel-to-concrete ratio allows optimum sizing of RCC structural members.

Ths BARQ Rebar Couplers increase production rates because of reduced installation time and simpler quality control requirements. Because of these differences, Labour requirements and costs will be substantially reduced.

Benefits:

- Practical and economical alternative to laps

- Fast cycle time: 30 second per thread

- One standard coupler for all splicing requirements (Standard/Position)

- Easy installation, no torque wrench required

- Shortens construction cycle times

- Manufactured under strict quality assurance plan ISO 9001

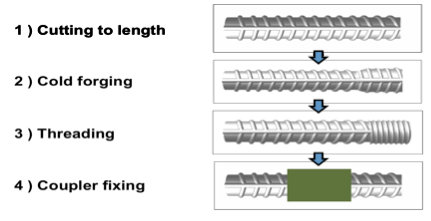

Sanfield system – The process

A FOUR steps operation with maximum output and performance

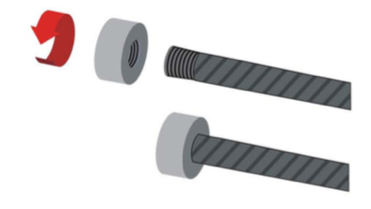

End Anchors

A convenient alternative to hooked bars or development length to provide end anchorages in congested areas. Sanfield standard anchorage heads are circular but can also be made to order in other shape or dimension as per requirement and also save steel, by avoiding the bending and remove the risk of rebar embrittlement, especially on large diameters.

Weldable Couplers

For composite construction where concrete reinforcement bars must be welded to structural steel, use Sanfield weldable couplers, which are specially made from low carbon steel and which have a designed chamfer for bevel welding.