SYSTEM

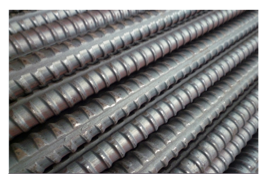

Pre-stressing Screw Thread Bar is a straight bar which has full thread, high strength, and high dimensional accuracy. The bar can be anchored at any section point with internal screw threads nuts.

It is widely used in large-scale water conservancy projects, industrial and civil construction continuous beams and large frame structure, road, rail and medium-sized cross-bridges, nuclear power plants and ground anchors and other projects. It can be easily connected and anchored, and has strong adhesion, tensioned safe, convenient construction, also save steel, reducing component size and weight.

Sanfield offer pre-stressing bars depending on the design requirements.

BENEFITS

- Homogeneous material, isotropic and with high tensile strength. Good resilience and resistance to fatigue.

- High impact strength at various temperatures.

- Large plasticity and very high ductility at low temperature.

- Low stress loss on fine thread.

- The system can be used in both cases of bonded and unbounded pre-stressing internal and external dismountable.

- Higher elongation compared to traditional products.

- Wide range of corrosion protection such as cement grout, wax injection or coating with plastic heat shrinking sleeve.

- High strength of bars leads to less congestion and ease of installation. Ability to detention and re-tension.

FULLY THREADED BARS APPLICATIONS

- Bridge Construction

- Lifting Bars

- Temporary or Permanent Stressing of Segments

ACCESSORIES

Spherical Nut, Hex Nut, Locked Nut, Couplers, Bearing Plate

QUALITY ASSURANCE

All component of the Sanfield pre-stressing bar system are manufactured under consistent quality assurance. Load-bearing components are all individually marked with a lot number that assure full traceability.

Traceability of bars is achieved through the MTC and the certificates of compliance provided together with the delivery notes.

A Certificate of Compliance and test reports are provided at the time of delivery.

SURFACE FINISH

No specific surface finish is required for pre-stressing bars; upon request, specific coatings are available.

CORROSION PROTECTION

Bars may be protected from corrosion by various means; to be specified by the client: cement grout, wax, plastic shrink films, paint, etc. These various types of protection may be applied on site or in a workshop.

INSTALLATION SEQUENCE

The installer should follow the Technical Specification in the Project Contract Documents. Installation sequence of Sanfield pre-stressing bars is dependent on application purposes, shear key, pre-stressing, post-tensioning, heavy lifting etc.