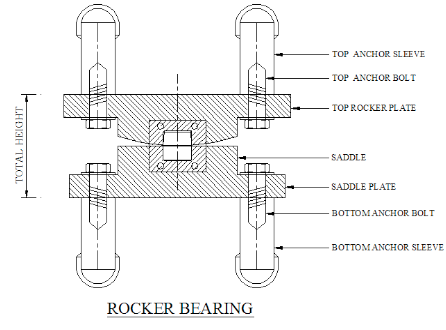

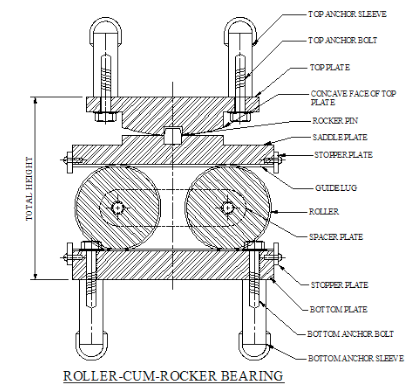

A typical Roller Bearing consists of a base plate, two or more rollers and a top plate. While the Rocker & Roller Bearing is made by providing a saddle and knuckle plate on top of the rollers. For the Rocker Bearings, the same arrangement except the rollers is provided. While the Rocker & Roller Bearing permits translation as well as rotation, whereas the Rocker Bearing permits only rotation. Similarly the Roller Bearing provides only the translation but no rotation.

Features of Spherical Bearings:-

Consist of Cylindrical concave and convex interface for accommodating rotation.

Rocker provides for free rotation by sliding.

Rollers provides for free movement by effortless rolling over action.

Able to satisfy high rotation & translation in one direction only.

The Bearing consists of the following Parts –

Roller: The rollers are the solid steel cylindrical shapes generally made of forged steel, cast steel or mild steel rollers are also used. These have machined surface to permit smooth rolling action.

Link Bar: All the Rollers are connected to each other with a link bar to ensure that they always move together and the in-between gap is maintained.

Tooth Bars: Rollers on the extreme end of a group of rollers are provided with tooth bars. The tooth bars rest into grooves provided in the knuckle plate on top and base plate at bottom. The purpose of tooth bars is to arrest movement of the rollers beyond the design movement. Alternatively, the rollers movement can also be restricted by providing the stopper bars in both top & bottom plates.

Rib and Notch: To arrest transverse movement between the roller and the base or knuckle plate, one or more longitudinal notches can be provided in the rollers and a matching rib in the base and top plate. The rib thus guides the rollers to roll only in the longitudinal direction and prevents any transverse movement.